Shower system does not operate fully (reduced or no water flow)

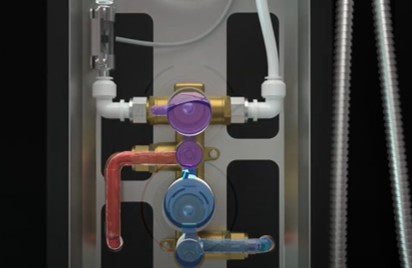

Hot or cold water supply isolation valve closed.

Debris has caused blockage in mixer.

Pressure difference between hot and cold supplies is too high.

Shower mixer/valve not functioning.

The disinfection process has caused debris in the form of corroded metal or scale to lift from the system pipework and cause the solenoids to block.

Check and open valve.

Isolate mixer and service strainers and cartridge see mixer instructions to service.

Adjust screws on mixer to balance. Or fit pressure reducer on high pressure supply.

Check valve, replace if necessary.

During the flushing of the pipework with the chemical present, as well as when coming to flush out the chemical back to freshwater, the Kelda Showers should be left until the last outlets in the building to flush, ensuring all tap outlets, bib taps and dead-legs have been flushed until there is no debris or discolouration present in the water. You may also have Group or Single outlet mixers before the showers, these will need to have the filter/strainers checked and cleaned. Failure to do this may result in the blockage of solenoids, causing them to either stick in the open position or not pass water.

If the solenoid valve in the Kelda Shower has become blocked it will need to be replaced.

Related Links

Frequently Asked Questions: Browse our FAQs

Find Out More

Maintenance: Keeping Kelda products performing safely and efficiently

Find Out More