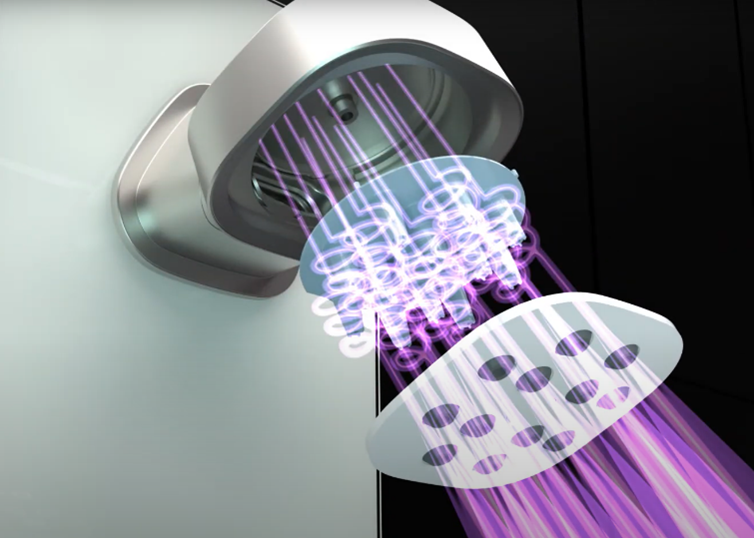

Looking after your Kelda shower

Watch Maintenance Video

Watch our latest maintenance video on YouTube here. Turn subtitles on.

Watch Installation Video

How to care for your stainless steel?

Cleaning and disinfection of air hoses

Daily/Weekly Hygiene

Quarterly Hygiene

6 Monthly Visual and Hygiene

Instructions for dismantling and reassembling head for cleaning

Best advice for disinfecting and reinstating Kelda Showers after a prolonged period of unuse.

Can't find what you're looking for?

Related Links

Testimonials: Discover what our clients have to say about Kelda

Find Out More

Kelda Showers are recognised within Appendix Q of the UK governments SAP and RdSAP

Find Out More